Sustainable Waste and Secondary Resource Management to Support the Energy Turnaround (wastEturn)

wastEturn aims to optimise the contribution of Swiss waste management to the “Energy Turnaround”, that is, the shift from non-renewable to renewable sources and reduction in overall energy consumption. The project looks beyond direct energy contribution by also analysing indirect savings, while considering environmental performance, financial viability, and political feasibility.

Two cases relevant to the Energy Turnaround are analysed: municipal solid waste (MSW) for material or energy recovery, and liquid industrial waste (IW) incinerated in waste-to-energy facilities. The management of MSW and IW is optimized under a set of future conditions, such as different energy scenarios and waste compositions. Once optimal waste management systems are identified, researchers and representatives from government, industry, and civil society will explore pathways to such systems and co-develop strategies to start moving along preferred pathways.

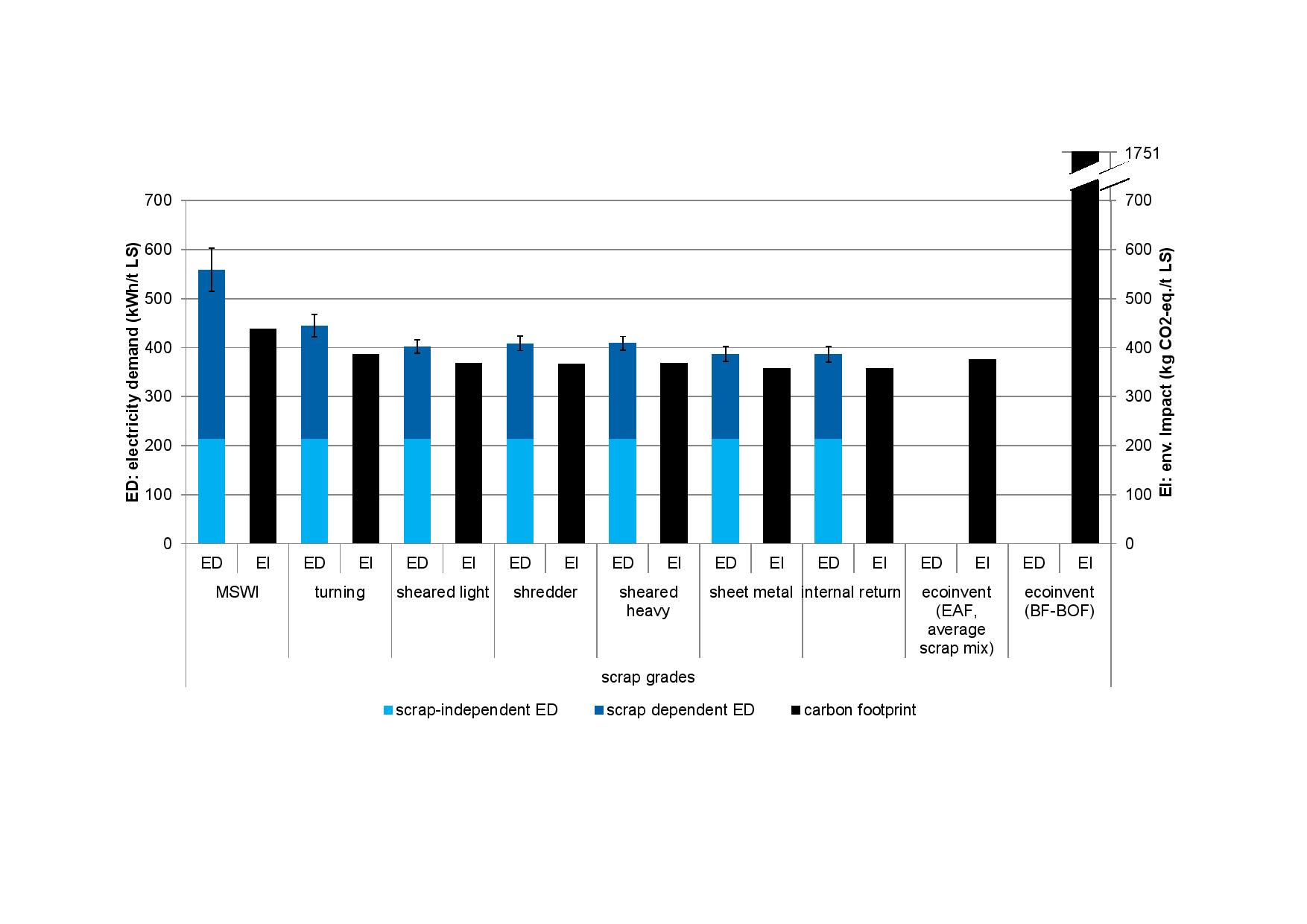

Published results include the quantification of scrap quality dependent electricity consumption for steel recycling and the investigation of current recycling rates of MSW fractions. The first study highlights the relevance of secondary resource quality for the case of steel. Low-quality scrap can increase the electricity demand of electric arc furnaces by 32% compared to average scrap. The second study reveals a higher improvement potential than previously thought. Still unpublished, a social network analysis of the revision of a major waste regulation highlights a sparse and quite centralized cooperation network. Few actors had profound influence on the legislative process and cooperation tends to occur more within actor groups, yet some of the strongest ties can be observed between the actor groups.

The vision of Professor Kurt Hungebühler and his team is a chemical industry that serves society with innovations based on sustainable process and product technologies. They recognize that responsible and carefully integrated development of chemical technology is the key to further progresses toward sustainability in safety, public health and environmental protection. A proactive approach to the design of environmentally benign chemical processes and products is, in their mind, clearly the direction where the chemical industry must go, and where they can contribute.