Avoiding Fatigue Cracks in High Temperature Power Plants Components

The extension of pre-existing or in-service generated defects by fatigue can be avoided in high temperature power plant components by informed mechanical analysis which fully acknowledges the influences of oxidation and creep interactions. This is the focus of the HTFCGT (Fatigue Crack Growth Threshold Stress Intensity Factors in Power Plant Materials at High Temperatures) project.

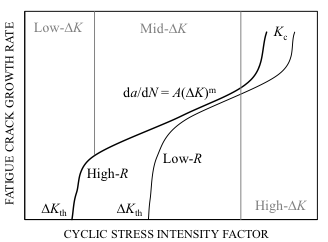

Traditionally, fatigue crack growth rates have been correlated with cyclic stress intensity factor (DK). The threshold value of this fracture mechanics parameter (DKth) is the maximum value of DK below which fatigue cracks do not grow. With a knowledge of this parameter it is possible to determine the cyclic stress below which a pre-existing or in-service generated defect of a given size will not extend in critical power plant components.

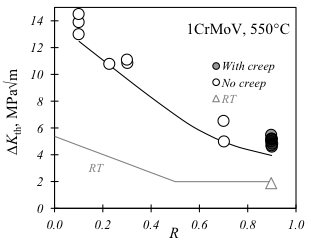

Experimental observations have shown that at high temperatures, DKth values for a number of power plant steels are higher than those determined at room temperature due to premature crack closure induced by plasticity and oxidation. This characteristic feature of low-DK behaviour may be advantageously exploited when considering the defect tolerance of power plant steels at high temperatures.

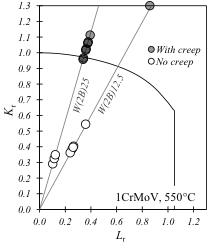

Creep cracking is not usually a problem for high temperature components subjected to high frequency fatigue loading conditions in the low-DK regime, apart from when the mean stress (K) is very high. It is shown that the risk of cracking in these circumstances may be effectively predicted using a time-dependent failure assessment diagram approach, thereby improving the effectiveness of high temperature defect assessment of power plant for energy systems.

The work is being conducted by the external page High Temperature Integrity Group (HTIG) of the Empa Laboratory for external page Mechanical Integrity of Energy Systems led by ESC member Prof. Dr. Edoardo Mazza.

The HTIG-Group develops new high temperature mechanical assessment procedures, primarily for energy systems, and verifies their effectiveness by service-like benchmark testing complemented by engineering metallurgical condition assessment