Ultra-compact and highly efficient battery interface for traction applications

Approximately one-third of the worldwide primary energy is consumed in the transport sector. In order to reduce the environmental impact of the transportation, alternative propulsion systems as for example hybrid electric vehicles are investigated. Such concepts enable amongst others to recuperate energy during braking, which reduces the total energy consumption. This project looks at an ultra-compact and highly efficient battery interface for traction applications.

Concepts like hybrid electric vehicles enable amongst others to recuperate energy during braking, which reduces the total energy consumption. In addition to cars, hybrid propulsion concepts are recently also investigated for locomotives, which are extended by an on-board battery system.

By recuperating breaking energy and by reusing it during the acceleration of the train, the power fluctuations in the railway grid can be significantly reduced and enables an additional degree of freedom for designing highly efficient locomotive propulsion systems. In addition, with the energy stored in the batteries, the locomotive can drive on not electrified tracks without a diesel engine avoiding air pollution and emission of greenhouse gases. This is especially important in congested areas, stations, and shunt yards.

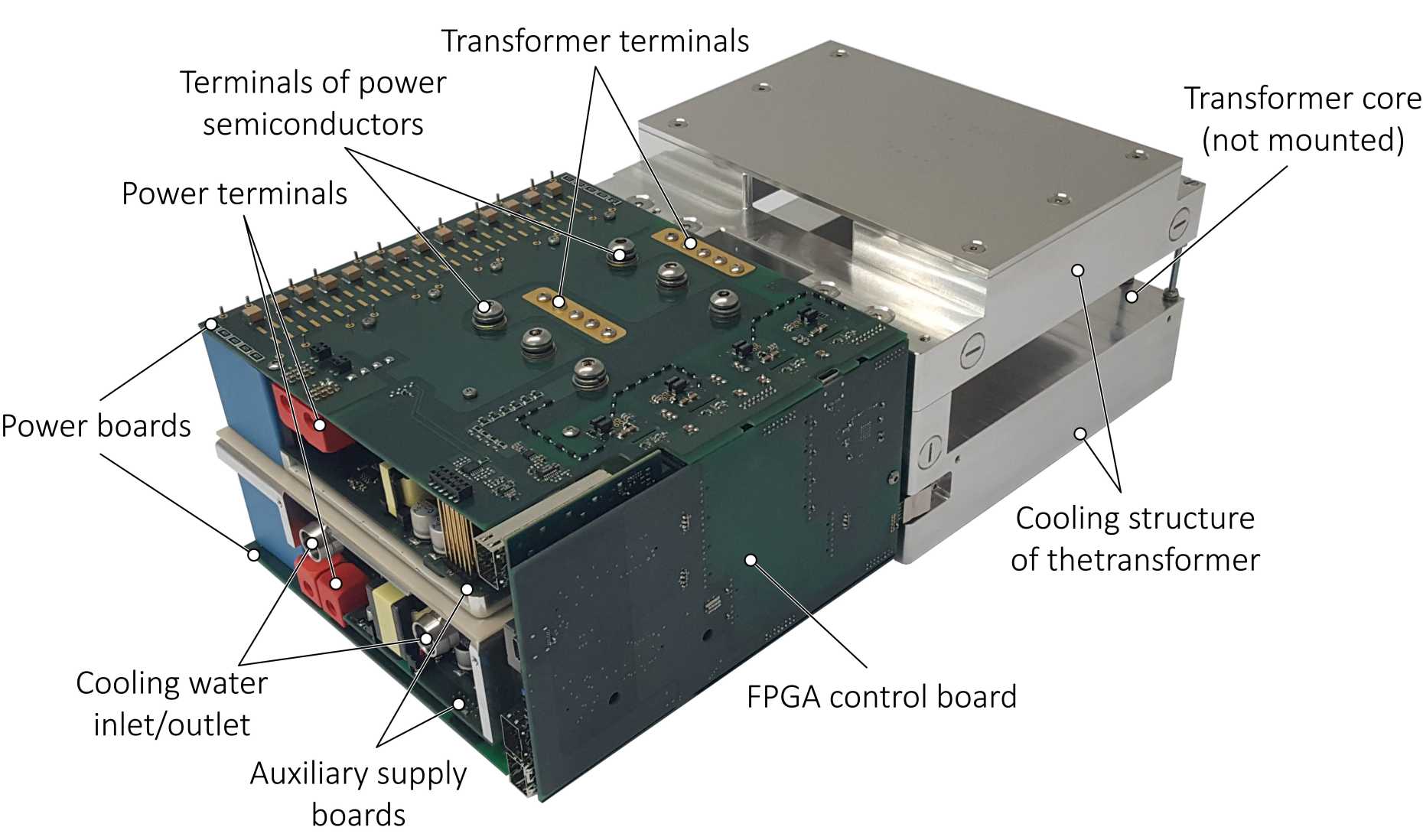

In the considered project, a battery system with a voltage range from 518V to 835V is integrated in a locomotive and interconnected to the 2.8kV drive bus via a bidirectional and isolated DC-DC converter system. Due to the severe space limitations in the locomotive, a very high power density and, consequently, also a high efficiency of the converter system is mandatory. Especially, the required isolation voltage poses a challenge in achieving the high power density of the overall system. By numerically and analytically modelling and optimizing the converter system as well as by advanced cooling concepts, an outstanding power density of 6kW per liter at a nominal efficiency of 98.7% has been achieved. In the Figure 1, the prototype of a 50kW module of the modular converter system is shown, which is currently tested at the Laboratory for High Power Electronic Systems.

The people involved in this project are Milos Stojadinovic, and ESC member Professor Jürgen Biela. Prof. Biela is head of the Laboratory for High Power Electronic Systems (HPE). The research at the Laboratory for High Power Electronic Systems (HPE) focusses on high power converter systems including operation at medium voltages required for example in future energy distribution for renewable energy sources or in traction applications.